These springs are manufactured according to the specifications of DIN 2093 standards which recommend thickness of more than 6 mm supporting surface. Spring Loaded Design The basic spring loaded pressure relief valve has been developed to meet the need for a simple reliable system.

Belleville Spring An Overview Sciencedirect Topics

Outside diameter 60 mm to 800.

. Disc springs to DIN 2093 Group 1 Group 2 Group 3 Disc springs to Factory Standards or other as required. MD-8 Spring design Leaf spring design guidelines explained here is the simplest version of the whole leaf spring design procedure. Disc Spring Stack in Stripper Assembly.

Guidance of disc spring stacks. The solid model of a Belleville spring washer is completely decided by its four geometric. ¾-inch maximum outside diameter 2 inches free length 35-pound load at a ½-inch deflection.

A minimum of 55 HRC is advisable otherwise the surfaces. Proper guidance and location of disc springs is essential to their performance and will ensure that the desired characteristics and repeatability is. We have custom design program to assist our customers.

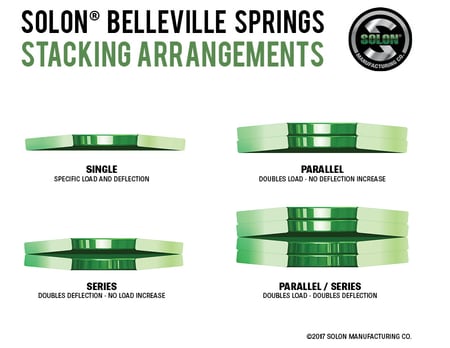

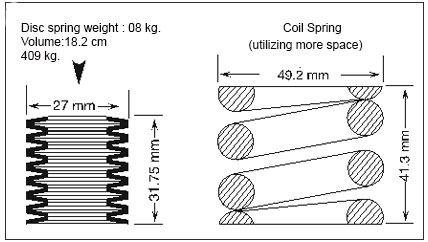

Belleville spring disc spring and conical compression washer are all names for the same type of spring. Disc springs can used as single or multiple units. Helpful Tips For Installing Disc Springs.

The surface of guide elements is dynamic disc spring applications always has to be harder than the disc springs themselves. Determine the fully loaded condition of the Disc Spring. Standard Disc Springs DIN 2093.

Ad Easy online search includes pricing and specifications for over 25000 springs. STanDarD Disc springs - Din 2093 Disc springs to DIN 2093 Group 1 Group 2 Group 3 Disc springs to Factory Standards or other as required Size range. Spring washer is then generated through rotating the slanted surface along its central axis.

Disc Springs are manufactured to DIN 2093 and designed as per DIN 2092. File Type PDF Flat Spring Design Guide solve for D. This may be specified by a length of.

When stacked in multiple unitsthey can be stacked in series to. Design a helical compression spring for the following conditions. A Belleville spring is a conical shaped disc that will deflect flatten at a given rate.

Additional typical disc spring applications are. A disc spring is a conical shell spring which is loaded along itsaxis. Disc springs always need a guide element to prevent lateral movement.

When forming a bend in a spring material it is important to remember Spring Back. Outside diameter 60 mm to 800. Disc Spring 15 x 52 x 04 lo 095 to DIN 2093 Specification Cycling from 50 to 75 deflection.

Those who use the information are reminded of. The guide can be on the outside D e or the inside D i of the springs. August 15 2007 33.

Depending on the hardness of the material all spring materials will exhibit some form of. 1 At 75 deflection select the greater of tensile stress points dor 1002Nmm 2. Ad Browse discover thousands of brands.

Power transmission components such as clutches brakes. Read customer reviews find best sellers. Ad Setup Auto-Reorder Always Have the Disc Springs You Need On-Hand.

Springs that follow this. Disc Springs are available with or without contact flats. Specify the force required for the Disc Springs to exert in the minimally compressed condition.

Series Sp Belleville Spring Index Fan Disc Corporation Fan Disc

A The Schematic Of A Conventional Disc Spring Geometry B Download Scientific Diagram

Disc Springs Calculation Formulas Tokai Spring Industries Inc

Belleville Spring Technical Notes Disc Spring Tech Notes

Disc Spring Din 2093 Disc Springs Manufacturers Suppliers Mumbai

0 comments

Post a Comment